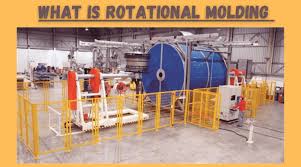

Plastics Rotomolding is actually a method accustomed to develop hollow plastic-type products including toys, storage containers, and furniture. It is an extremely adaptable process that requires utilizing heating and pressure to produce plastic-type into the wanted condition. The procedure demands minimal energy in comparison to conventional shot molding and might generate complicated shapes using a higher level of details. Learning the basics with this approach will help you determine should it be the best choice to your manufacturing undertaking.

The Essentials of Rotomolding

The Rotomolding procedure begins with a hollow mold (or “die”) that has been heated in a oven. The heated expire will then be full of powdered plastic material substance that is then rotated slowly on two axes so the fabric equally jackets all surface areas. Following the materials has become applied, it is permitted to cool and firm up in the perish before it is removed from the stove. This generates a hollow product with easy wall space with no seams or welds.

The Benefits of Rotomolding

Rotomolding delivers many key benefits in comparison with other plastics production procedures including injection molding or blow molding. Very first, as there are no welds or seams, rotomolded parts are generally stronger than components developed via other techniques. In addition, since the molds used in rotomolding are relatively basic and low-cost to make, it permits far more style versatility than other procedures – which makes it perfect for simple-operates or personalized apps. Finally, rotomolding also makes use of considerably less energy than other procedures because of its low temperature needs and slow rotation rate – making it a fantastic selection for jobs focused on sustainability.

Bottom line:

To summarize, rotomolding is surely an incredibly flexible plastics developing process that offers numerous essential benefits over option approaches like injection molding or blow molding. By finding out how this technique performs and what its benefits are, you may make a well informed decision about whether it’s suitable for any project. Regardless of whether you’re trying to find complicated designs with high degrees of depth or something that is less difficult like gadget generation -rotomolding can be just what exactly you need!